Your Demand, Our Solution

We create with passion

Phenol-Formaldehyde Resin Manufacturers

Find the legacy of VESKN Industry, a top-tier manufacturer & producer of high-grade Phenol-Formaldehyde Resin, having our nerve centre or headquarters in Bhiwadi, the heart of multiple industries.

Emerging as a key player with innovative ideas, helping industries get quality resin in this era of contamination. With a team of experienced workers & chemists, we as VESKN have established ourselves as one of the top-notch resin manufacturing units. We specialize in Phenol-Formaldehyde Resin production to deliver superior quality & meet diverse global industrial demands.

Emerging as a key player with innovative ideas, helping industries get quality resin in this era of contamination. With a team of experienced workers & chemists, we as VESKN have established ourselves as one of the top-notch resin manufacturing units. We specialize in Phenol-Formaldehyde Resin production to deliver superior quality & meet diverse global industrial demands.

Phenol-Formaldehyde Resin Manufacturers

Find the legacy of VESKN Industry, a top-tier manufacturer & producer of high-grade Phenol-Formaldehyde Resin, having our nerve centre or headquarters in Bhiwadi, the heart of multiple industries.

Phenol-Formaldehyde Resin Manufacturers

Find the legacy of VESKN Industry, a top-tier manufacturer & producer of high-grade Phenol-Formaldehyde Resin, having our nerve centre or headquarters in Bhiwadi, the heart of multiple industries.

Emerging as a key player with innovative ideas, helping industries get quality resin in this era of contamination. With a team of experienced workers & chemists, we as VESKN have established ourselves as one of the top-notch resin manufacturing units. We specialize in Phenol-Formaldehyde Resin production to deliver superior quality & meet diverse global industrial demands.

Novolac Resin

Resol Resin

Modified Resin

Types of Products

Having a resin manufacturing plant, VESKN Industry operates the latest production facilities with properly equipped technology. So that, we can produce a diverse range of resins, meeting the demands or requirements of various industries. Moreover, we also provide a modified version of Phenol-formaldehyde resins tailored to specific client requirements. At VESKN, we prioritize excellence, quality, commitment, & innovation. So, based on the ratio of phenol to formaldehyde as well as the reaction conditions, different types of phenol-formaldehyde resins that we obtain are Novolac, Resol, & Modified versions of Resins.

We are present globally

- Quality of product

- Timely delivery of product

- Fulfilment of quantity of product

- Consistency of product

- Price of product

VESKN Industry

VESKN Industry

Many factors make us who we are, such as we believe in adapting to the latest manufacturing & production trends. We are expanding our capabilities to provide maximum value results to the clients.

Our

Mission

Focusing on producing superior quality products with consistency by utilizing our latest equipment & machinery.

Our

Vision

We will soon thrive as a top-class leader in the field of chemicals, resin manufacturing & production.

Our

Policy

Veskn has some strict policies regarding safety measures, material & chemical quality, product testing, production, & so on.

Industries We Serve In

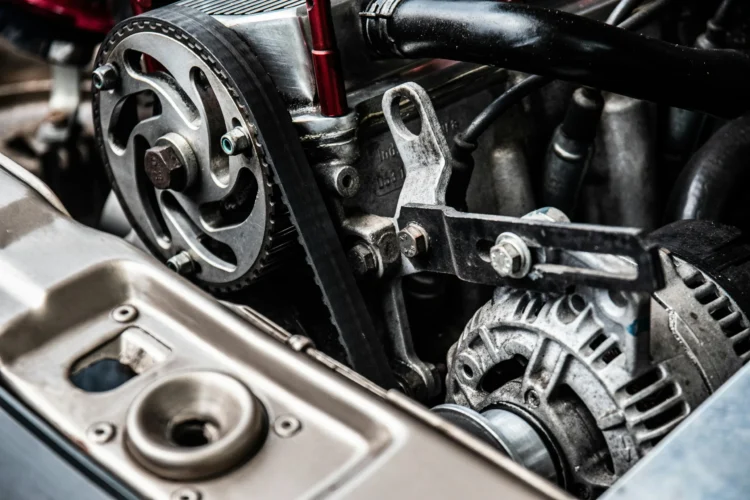

Automobile Industry

Resin plays a vital role in the automobile market. It is commonly used in adhesives, coatings, and plastic components such as bumpers, interior trims, etc. Resins also provide aesthetic appeal, durability, and weather resistance. Their excellent adhesive properties and moisture resistance make them ideal for use in various devices.

Examples of Resin Applications in Automobiles:

- Body Panels

- Interior Components

- Under-the-Hood Components

- Electrical Components

- Paint Systems

Abrasives

Phenolic resins play a crucial role in the production of various abrasive tools, acting as a strong and durable binding agent. They are particularly valued for their excellent thermal stability, mechanical strength, and resistance to chemicals and water.

Types of Phenolic Resins Used in Abrasives

- Novolac Resins: These resins require a curing agent (e.g., hexamine) to crosslink and harden. They are commonly used in bonded abrasives like grinding wheels and cutting discs.

- Resole Resins: These resins are initially soluble but become infusible and insoluble upon curing. They are widely used in coated abrasives like sandpaper and belts.

Foundry

Resins play a crucial role in the foundry industry as binders for sand to create molds and cores for casting metal parts. These resins provide the necessary strength and stability to the sand molds, ensuring accurate and high-quality castings.

Phenolic Resins:

- Most commonly used due to their excellent thermal stability, mechanical strength, and moisture resistance.

- Used in various processes like no-bake, cold-box, and hot-box.

- Provide good dimensional accuracy and surface finish to the castings.

Rubber Industry

Phenolic resins are used in rubber compounds to provide increased toughness, hardness, abrasion resistance, stiffness, & tear resistance. Resins play a crucial role in the rubber industry, enhancing the performance and properties of various rubber products.

Key Benefits of Using Resins in Rubber:

- Improved Mechanical Properties: Enhanced hardness, tensile strength, tear resistance, and abrasion resistance.

- Enhanced Processing Performance: Improved mixing, extrusion, and molding properties.

- Improved Adhesion: Better bonding between different layers of rubber compounds.

- Improved Heat and Aging Resistance: Increased durability and longevity of rubber products.

- Reduced Cost: Resins can often be more cost-effective than other additives.

Refractory

Phenolic resins are commonly used as binders in the refractory industry due to their excellent thermal stability, mechanical strength, and carbon-forming properties. They contribute to the overall performance and durability of refractory materials, which are essential in high-temperature environments.

The 3-dimensional structure is essential for enhancing carbon yield & catalytic graphitization is one of the most effective methods to induce carbon crystallization.

Filtration

Resin removes chlorine & sulfur. The small resin beads are used to attract hardness-causing ions as well as to replace them with harmless sodium ions.

Resins are invaluable tools in filtration processes, offering efficient and selective removal of contaminants.

Their versatility and effectiveness make them essential components in various industries, ensuring the quality and purity of water and other liquids.

Mica & Wood

Mica is a naturally occurring mineral that is often used in cosmetics and other products due to its reflective and shimmery properties.

Some cosmetic products may contain mica powder that has been coated with a thin layer of resin to improve its color stability and adherence to the skin.

Mica is used in resin to give it a solid and opaque color. As mica minerals are insoluble, the numerous small particles in a mica powder pigment will retain their form when added to resin.

For this, apply a small amount of resin onto a wax surface or into a small cup & mix the mica powder into the solution, until it is completely dissolved. Then add this to your main solution.

Resin is commonly used in woodworking for various purposes, including:

- Adhesives: Resins, such as epoxy and polyurethane, are used to bond wood pieces together.

- Coatings: Resin-based coatings, like varnishes and lacquers, are used to protect and enhance the appearance of wood surfaces.

- Fillers: Resins are used to fill gaps and imperfections in wood surfaces.

- Decorative effects: Resin can be used to create decorative effects on wood surfaces, such as river tables or epoxy resin art.

Looking to make a career with us!

Click the "Join Us!" button and enter your details. We'll contact you soon after the details are submitted via email.

Our Top Clients