What we do?

Veskn industry is a manufacturer of top-quality Phenol Formaldehyde Resin, which goes by the name of vesolac phenolic resin, for different industries like:

- Automobile Industry

- Paper Industry

- Rubber Industry

- Fibre Industry

- Refractory Industry

- Tyre Industry

- Rice rollers (Food Industry)

- Filter Industry

We also prepare tailored phenol formaldehyde resin according to the specifications of our customers, for example, one of our customers, which is a manufacturer of cork rubber sheets, provided us with a sample of resin that is imported by the user. After research in our lab on the composition and structure of the resin, we developed a grade that suits our customer and meets their requirement. The example above is the reason we have a saying, “We not only provide what we have, we also provide what you want.”

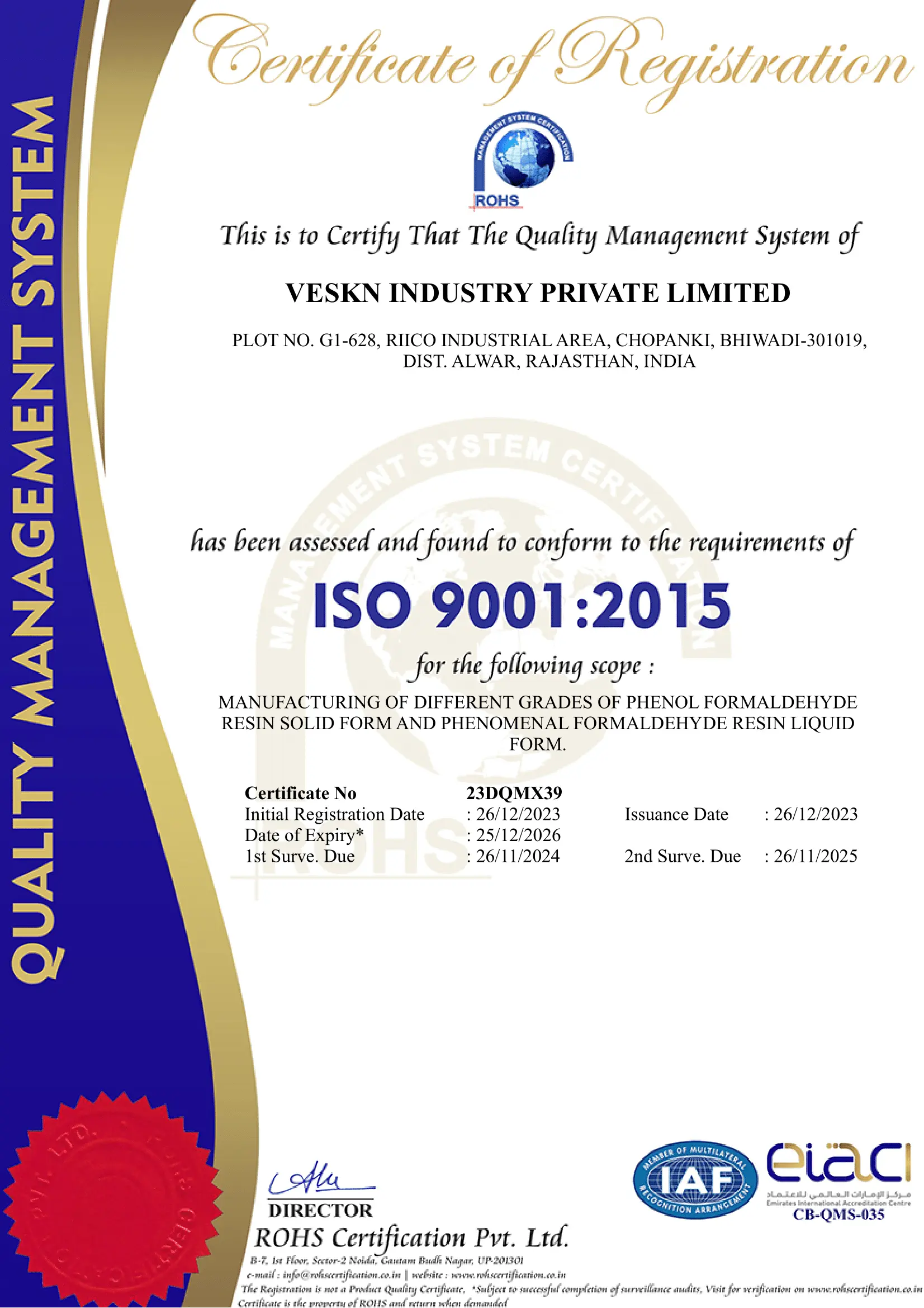

Why Choose Us?

In today’s market, it is not difficult to find a vendor/supplier, but to find a vendor/supplier who can meet its customers’ requirements at different stages of business, which are

- Quality of product

- Consistency of product

- Price of the product

- Fulfillment of the quantity of the product

- Timely delivery of the product

Now the question comes of how we are going to meet these requirements of a customer’s, well, that answer relies on VESKN’s manufacturing unit.

Team Expertise

All this is possible because of our team of seasoned professionals, comprising chemists with over twenty years of experience. The workforce includes skilled machine operators, automation specialists, and grinding experts. With a focus on expertise, VESKN ensures that its team remains at the forefront of technological advancements, and these two points are the answer to the question about “Consistency of the Product.”

Process

What makes us confident about our product is our process of each and every part of the day-to-day tasks of material production, whether it is material handling or chemical reaction.

- Raw material handling: The journey of our product starts with choosing the right raw material, which we do by ensuring testing each lot of raw material we use according to the parameters set by our experts, so that there will be no chance of low-quality raw material entering our premises. Secondly, we have designed lifts and pipe systems for raw material transfer, which led us to maximum safety.

- Reaction: Now, the most important part of the process occurs, which is a chemical reaction. Our cutting-edge machinery, equipped with the latest technology, helps us in real-time monitoring each and every crucial parameter of the reaction, due to which we can carry out our reaction effectively according to our requirements in each reaction batch.

- Semi-Finished/Finished Good Handling: As soon as our reaction process ends, our semi-finished/finished goods go under various quality tests, which ensure we have the same quality consistently every time. Once the material passes the test, it goes into a storage area where it is distributed according to its properties into different areas, so we can easily manage it.

- Dispatch: Once quality assurance is confirmed, our packing chain systems confirm accurate measurement and uniform packaging, maintaining product integrity and safety. Finally, products are prepared for dispatch, and our efficient dispatch procedures ensure timely delivery.

Top Clients we are Serving

- ASM Castings

- Golden Rolls

- AVS Brake Linings

- Balaji Ceramics

- NU-Cork

- Steelage Refractories

- Siddharth Brakes

- AFT Automotive

- Nabco Microtech